2025

ACQUISITION OF AHWION TECHNOLOGIES INTO THE HÄRING GROUP

With AHWION, we combine cold forming and machining in an integrated manufacturing process for complex precision components – efficient, resource-conscious, and focused on the mobility of the future.

2024

20TH ANNIVERSARY CELEBRATION OF HÄRING TAICANG

Two decades of commitment, growth, and collaborative partnerships: Häring Taicang marked 20 successful years with a festive event. Employees, partners, and guests recognized the development of the site and celebrated together the company’s impressive success story in China.

2022

OFFICIAL OPENING OF THE US LOCATION

The American location, Haering Precision USA LP, was officially inaugurated with a festive Grand Opening – delayed due to the pandemic, but no less significant. The celebration marked an important milestone in the company’s international expansion and was joyfully commemorated together with employees, partners, and guests.

2022

Expansion into the hydrogen business area

We are focusing on forward-looking technologies and expanding our portfolio to include high-quality machining of materials for hydrogen applications.

2021

Founding of "AHWION Technologies"

Together with HEWI G. Winker GmbH & Co. KG, we founded the joint venture "AHWION Technologies". This strategic partnership bundles our expertise of innovative product developments.

2021

Company anniversary

60 years of Anton Häring KG - the technology company celebrates its anniversary and focuses on strong future topics.

Because thinking of everything means above all: thinking ahead.

2019

Construction completed at site in Lavonia, GA, USA

On a site of over 150,000 square meters, there is a production space of 15,000 square meters with its own academy and the company restaurant, ANTONIS.

2018

Expansion of the Academy in Germany; rebuilding of the production office.

The space for training was doubled as a result of the expansion of the Academy basement.

The production office also has a new luster following its modernization.

2017

Production expansion in Poland

At the location in Poland, we acquired the neighboring business ZSM. The renovation is completed in this year and, as a result, our production department grows about 20,000 sq m.

2016

New building in the USA

Häring continues to advance its internationalization and begins with the design as well as the construction of a new location in the US state of Georgia.

2016

Expansion in China

The expansion in Taicang was completed in January. As in Bubsheim and in Poland, there is now also a Häring academy in China.

Production: 12,000 sq m

Basement: 7,000 sq m

2016

Academy and cafeteria in Poland

The Poland location gets its own academy building and a company restaurant.

2014

Expansion in Poland

The expansion in Poland is completed this year. Häring's production space has grown to 70,000 sq m.

2013

Expansion Bubsheim

The Häring team keeps growing. This year, the expansion is completed and the production area increases to 23,000 sq m.

In addition, a cogeneration unit is completed at the Bubsheim location.

2011

Company anniversary and anniversary of the Poland location

Anton Häring KG celebrates its 50-year anniversary at its headquarters in Bubsheim in southern Germany. At the same time, 1,200 employees of Haering Polska celebrate their 10th anniversary and the steady growth of their location.

2010

New location in China

The new facility "Haering Precision" is being opened in the Chinese city of Taicang.

2008

Company restaurant in Bubsheim

Häring provides its employees with healthy nutrition at work: The new company restaurant is opening its doors in the headquarters in Bubsheim.

2006

Expansion in Poland, new construction in China

In Poland, thanks to an expansion, Häring can now produce on 25,000 sq m. In China, construction has started on the new location in Taicing (6,000 sq m production area; supply of the Asian market).

2005

Anton Häring Academy

The inauguration of the 3,300 sq m Anton Häring Academy symbolizes a comprehensive expansion and professionalization of our in-house training and further development. It is also the start of the training of 18 Chinese employees (6 engineers and 12 skilled workers) for the future location in Taicang. In 2005, the production hall was expanded as well ( multi-spindle equipment and machines for further processing together with the production department's grinding shop).

2003

Quick growth in Poland

The number of employees has already increased to more than 190.

2002

New location in Poland

Häring positions itself for the markets of the future and opens a new location south of Lodz in the Polish city of Piotrków. Area: 10,000 sq m Employees: approx. 70.

1998

Expansion Bubsheim

The continued growth requires a new expansion of production facilities to 19,000 sq m as well as the introduction of a driverless transport system.

1995

11,000 sq m

An expansion increases the area of the production hall to 11,000 sq m.

1994

MDE system

With the introduction of the MDE system for the collection of machine data, Häring is able to increase its productivity tremendously.

1993

Turned parts production for BOSCH

Häring produces various turned parts for the new injection valve (EV6) from BOSCH.

1992

New facilities

With a modern plant expansion, the floor space of the office and the mechanical engineering department is increased significantly.

1990

New production

With the development of a gear tooth production for the 232 employees, Häring optimizes production.

1986

New building, high-tech, manpower

The production halls are increased to 9,500 sq m and the first CNC lathe is purchased. Current number of employees: more than 200.

1983

More precise technology

New machines for superfinishing and 8-spindle machines expand the potential of the company.

1980

Our team gets its own tennis court

From now on, employees can end their work day with a bit of exercise. The construction of our tennis court gets an enthusiastic reception. The company also serves as a sponsor by purchasing the initial equipment.

1979

New plant

In order not to stifle the growth of the company, it moves into a new building and the production department is expanded through gearing technology. As a result, the 94 employees benefit from more space and high-tech.

1978

In-house tool grinding shop

For more speed and higher quality, Häring begins to rely on its own tool grinding shop. Indexing table machines expand the production department.

1974

Investment in new technology

The first multi-spindle machine is purchased for the 60 employees.

1973

Constant growth

By now, the company has 45 employees and owns more than 60 Swiss-type lathes and parting-off automatic machines.

1971

More space, more technology, more employees

The company moves into an extension, where 32 employees manufacture products using newly purchased Swiss-type lathes.

1968

New plant, new products, new employee benefits

When moving into the new production plant, the 14-employee company also changes its portfolio and makes the switch from standard parts to designed turned parts that were manufactured using new Swiss-type lathes. In 1996, the company starts training apprentices and the employees are able to take advantage of additional benefits in the areas of pensions and life insurance.

1964

Construction of a new plant

For a long time, there had been insufficient space in the barn. As a result, the first plant is built.

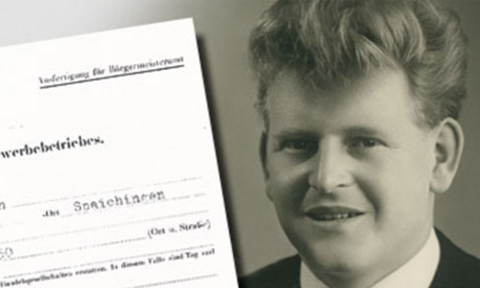

1961

Founding

Anton Häring, a mechanic and technician who was only 21 at the time he founded Anton Häring, Werk für Präzisionstechnik (plant for precision technology). Using two parting-off automatic machines in his parent's barn, he begins with the production of standard parts (screws, nuts).

2025

Übernahme von "AHWION Technologies" in die Häring Gruppe

Mit AHWION vereinen wir Kaltumformung und Zerspanung in einem integrierten Fertigungsprozess für komplexe Präzisionsbauteile – effizient, ressourcenschonend und ausgerichtet auf die Mobilität der Zukunft.

2024

Jubiläumsfeier anlässlich 20 Jahre Haering Taicang

Zwei Jahrzehnte Engagement, Wachstum und partnerschaftliche Zusammenarbeit: Mit einer feierlichen Veranstaltung blickte Haering Taicang auf 20 erfolgreiche Jahre zurück. Mitarbeitende, Partner und Gäste würdigten die Entwicklung des Standorts und feierten gemeinsam die beeindruckende Erfolgsgeschichte des Unternehmens in China.

2022

Feierliche Eröffnung des US-Standorts

Mit einem festlichen Grand Opening wurde der US-Standort offiziell eingeweiht – pandemiebedingt mit einiger Verzögerung, aber nicht weniger bedeutend. Die Feier markierte einen wichtigen Meilenstein in der internationalen Expansion und wurde gemeinsam mit Mitarbeitenden, Partnern und Gästen würdig begangen.

2020

Gründung Standort Tunesien in Tunis + Start mit dualer Ausbildung am Standort Lavonia, USA

Mit der Gründung des neuen Standorts in Tunis, Tunesien, setzt Haering seinen Wachstumskurs fort. Zeitgleich wurde am US-Standort in Lavonia erfolgreich das duale Ausbildungssystem eingeführt – ein weiterer Schritt in Richtung nachhaltiger Fachkräftesicherung und internationaler Kompetenzentwicklung.

2019

Feier in Bubsheim anlässlich 50 Jahre Ausbildung

Ein halbes Jahrhundert erfolgreiche Nachwuchsförderung: In Bubsheim wurde das Ausbildungsjubiläum feierlich begangen – mit Rückblicken, Erfolgsgeschichten und einem klaren Blick in die Zukunft.

2013

Start der dualen Ausbildung am Standort Taicang mit Unterzeichnungszeremonie

Mit einer feierlichen Unterzeichnungszeremonie begann am Standort Taicang ein neues Kapitel: Der offizielle Start der dualen Ausbildung markiert einen wichtigen Schritt in der Fachkräfteentwicklung nach deutschem Vorbild.

2012

Erweiterung des polnischen Werks um eine weitere Produktionshalle

Mit dem Bau einer weiteren Produktionshalle wächst der Standort in Polen weiter. Die Erweiterung schafft zusätzliche Kapazitäten und unterstreicht die strategische Bedeutung des Werks für die internationale Fertigung.

2009

Start der dualen Ausbildung nach deutschem Vorbild am Standort Piotrkow, Polen

Am Standort Piotrków begann die duale Ausbildung nach deutschem Vorbild – ein wichtiger Schritt zur nachhaltigen Fachkräftesicherung und zur Weitergabe technischer Exzellenz.

2004

Erteilung der Geschäftslizenz am Standort Taicang China

Mit der offiziellen Erteilung der Geschäftslizenz setzt Haering Taicang den Grundstein für nachhaltiges Wachstum und erfolgreiche Geschäftsentwicklung in China.

1999

Start internationales Trainingsprogramm

Know-how-Transfer für den Aufbau des Werks in Polen